Precision impeller machining

Crankshaft machining

Valve processing

Laryngoscope parts

Leading the high-precision machining industry

High-precision metal processing for parts, with products used in medical devices, semiconductors, heavy industry, aerospace, and other fields.

Micron-level precision machining

By utilizing a high-rigidity CNC machining center and a coordinate measuring machine, a machining tolerance of ±0.005mm is achieved.

Customized solutions

It supports seamless integration of small-batch prototyping and large-scale mass production, enabling rapid response to customized customer orders.

Strict quality control

Establish an ISO 9001 quality management system, with a dedicated quality inspection process for each step of the process.

Our CNC machining capabilities

It is equipped with a large number of advanced CNC machining equipment such as DMG MORI and Mazak, as well as commonly used general-purpose machining equipment.

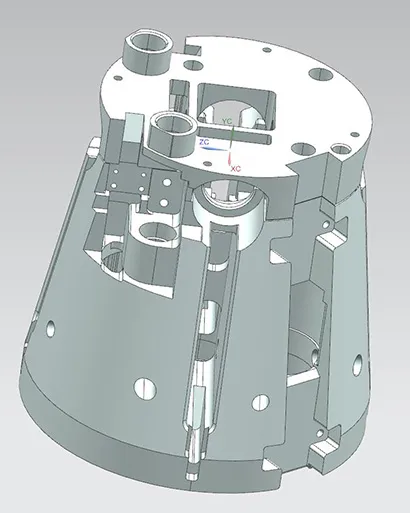

Core CNC Machining

Relying on five-axis CNC machining technology, we have overcome the difficulties in machining complex irregular structures, with tolerance control of ±0.002m.

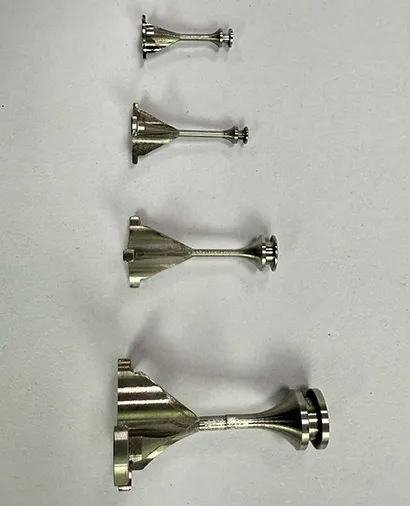

Robotic arm crankshaft parts machining

We specialize in high-precision robotic crankshaft machining, overcoming the challenges of machining complex curved surfaces with tolerance control of ±0.005mm. Leveraging 10 years of CNC experience and five-axis linkage equipment, we ensure stable batch delivery.

Dirty pacemaker impeller machining

Employing five-axis CNC precision milling technology, it overcomes the challenges of machining micro-thin-walled curved surfaces, with tolerance control of ±0.002mm, meeting the stringent precision requirements of implantable medical parts.

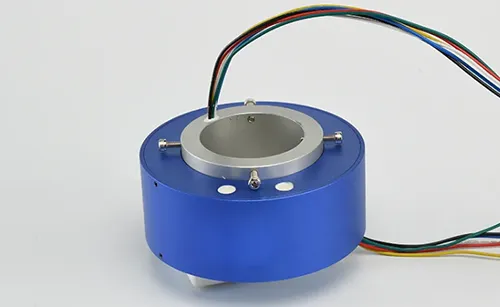

Custom conductive slip rings

Five-axis CNC precision machining overcomes the difficulties in machining concentric holes in multiple pathways, with tolerance control of ±0.003mm, meeting the customized requirements for high-speed signal transmission slip rings.

Customer processing cases

parts qualification rate

Quality Inspection Standards

Delivery period

Our CNC machining products

Sunpower Manufacturing specializes in custom high-precision component machining, focusing on robot joints, core medical device parts, etc.

BLOG

CNC machining, with its micron-level precision and automated efficiency, empowers multiple industries and overcomes the challenges of complex parts.

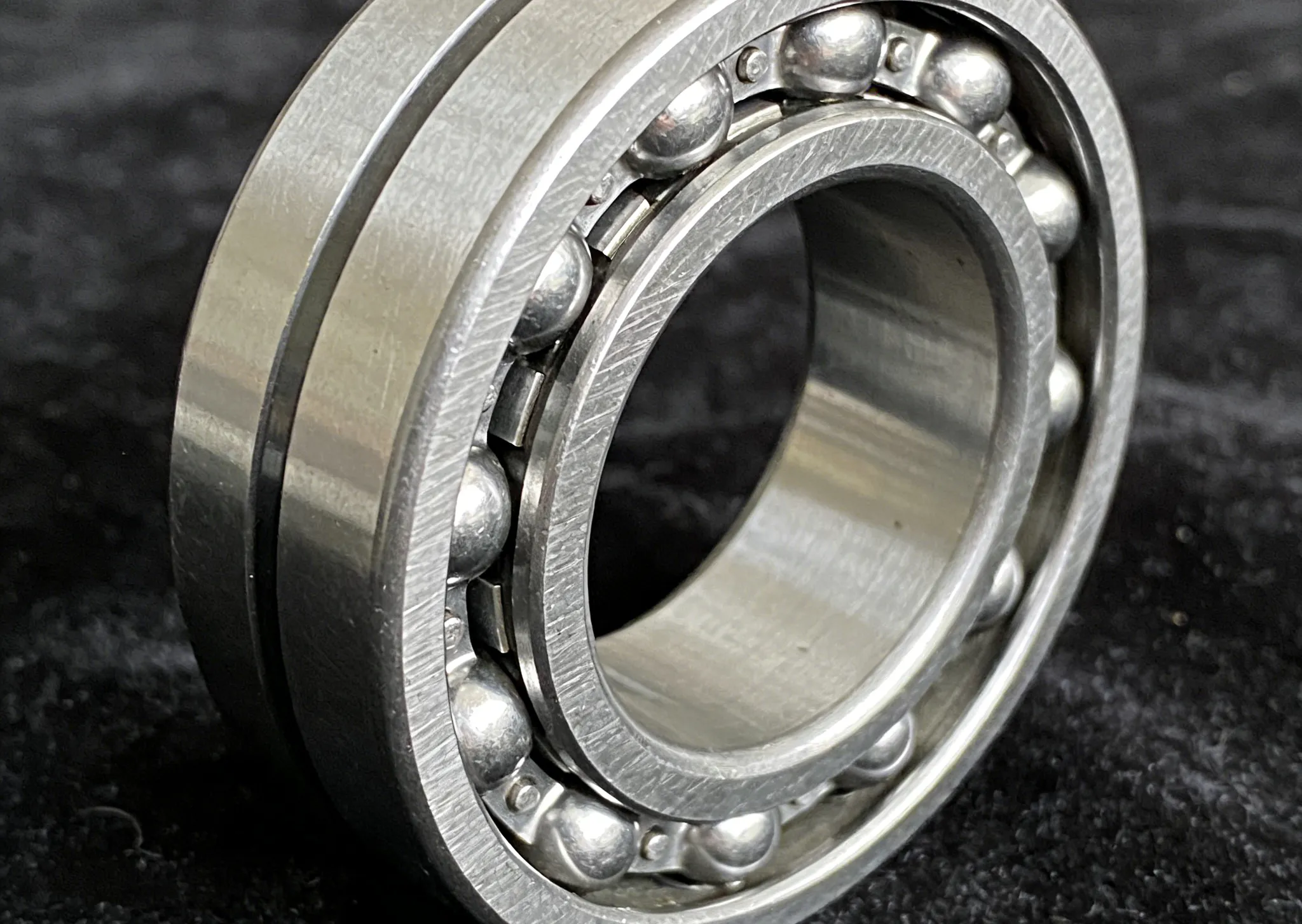

Rolling Bearing Processing Technology: Complete Guide for Bearing Components

A rolling bearing is generally composed of four parts: outer ring, inner ring, rolling elements and cage. According to the…

6 Critical Challenges in CNC Machining of Semiconductor Precision Components & Solutions

Semiconductor precision components are core components of semiconductor manufacturing equipment such as lithography and etching machines,and their processing accuracy directly…

Cardiac pacemaker parts manufacturing: Overcoming micron-level challenges with 4 major technological breakthroughs.

Cardiac pacemaker parts manufacturing stands as a critical link in the global medical device industry, integrating precision engineering, biocompatible material…

4 precautions should be taken when using slip rings.

Slip rings are precision components and therefore require careful handling. As core transmission parts that enable continuous rotation while conducting…

0.001mm Precision Guaranteed: Why CNC Machining Is Ideal for Premium Hearing Aid Parts

hearing aids have extremely high requirements for dimensional accuracy, surface quality, and biocompatibility in their core components (such as the…

What peoples say about us

Our cooperative clients highly recognize Sunpower Manufacturing for its high-precision machining quality.

Olivia

robot manufacturer

We’ve partnered with Sunpower Manufacturing multiple times. Their precision parts for robots meet all accuracy standards with tolerances controlled within ±0.005mm, and deliveries are always on time. We’ll definitely keep working together!

Emma

robot manufacturer

The custom robot joint components exceeded our expectations in surface treatment and wear resistance. They ran stably during assembly testing—truly a professional manufacturer in the high-precision machining field!

Lucas

Medical industry

For our non-standard requirements, the Sunergy team provided an optimized solution quickly. They not only solved machining challenges but also helped us cut costs. A reliable partner you can count on!