Our company

CNC machining factory-Sunpower Manufacturing is a high-precision manufacturing company integrating R&D, production, assembly, and sales services, providing one-stop processing services with a full range of equipment.

Equipment Introduction

We currently possess 30 CNC lathes, 51 CNC machining centers, 24 drilling and tapping machines, 5 milling machines, and a complete range of other precision equipment. To meet our customers’ high-quality product requirements, the company is also equipped with advanced testing equipment, including fully automatic coordinate measuring machines, 2D and 3D measuring instruments, height gauges, hardness testers, and salt spray testing machines.

Main Business

Our main business is the precision machining of metal parts, with products used in medical devices, semiconductors, heavy industry, and aerospace. We are dedicated to providing our customers with high-quality products and professional technical services.

CNC machining factory‘s Culture

Core Values

Seek development through quality and build the future with integrity.

Corporate Vision

Become a first-class precision manufacturing service provider.

Business Philosophy

Customer-oriented, strive for perfection, excellent quality, and credit first.

Quality Policy

Pursue excellence and prioritize quality.

Quality Control

Company Quality Objectives: To survive through quality and develop through reputation. “Striving for perfection, pursuing excellence, prioritizing quality, and professionally manufacturing first-class products” is our service philosophy.

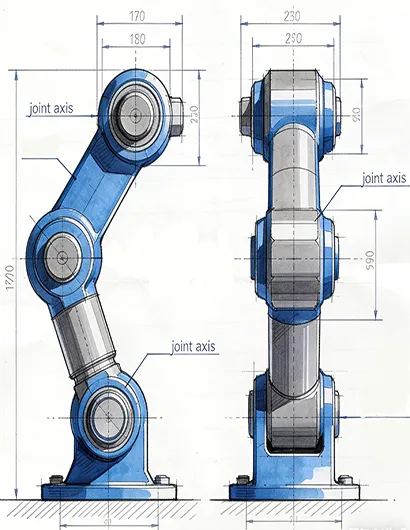

All products adhere to strict 5S quality inspection standards. To ensure uncompromising product quality, we have established rigorous quality control procedures aligned with ISO 13485 medical device quality management standards—the global benchmark for medical component manufacturing. We also continuously upgrade our CNC machining processes to deliver high-quality, high-precision parts for medical device, aerospace and robotics applications.

Precision per Drawing

Process and produce strictly in accordance with the drawing precision requirements.

Frequent Inspection & Waste Control

Inspect first and last pieces mandatorily, conduct patrol inspections every two hours, and ensure the defect rate is controlled below 5%.

100% Sample & Batch Sampling

Conduct full inspection for samples, with a sampling inspection rate of no less than 30% for batch parts, and ensure the product qualification rate is controlled

above 95%