Application industries

Conductive slip rings can be used in any electromechanical system that continuously transmits power and data signals in a 360° rotating manner. They are often referred to as conductive slip rings, brushes, adapters, slip rings, current collectors, rotary joints, current collectors, return rings, and commutators.Our products strictly adhere to the quality management system requirements of ISO 9001:2015, ensuring consistent precision and durability across every batch.

Intelligent robots

Medical devices,

Wind power generation

Smart security

Industrial applications

The unique advantages of our slip rings

Superior quality conductive rings & reliable bearings & guaranteed brush bristle quality & professional R&D team

360° smooth, unrestricted rotation fully meets the requirements for image, current, signal, and data transmission.

Made of precious metal wire; wear-resistant to ensure ultra-long working life – hundreds of millions of revolutions, maintenance-free.

Utilizes fiber brush technology; gold-to-gold multi-point contact ensures stable signal, current, and data transmission.

Compact structure, interference-free, high performance, low torque, low noise, smooth and reliable operation.

Complete product series; customized products according to customer needs; high-end quality and excellent service.

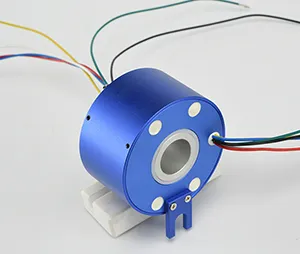

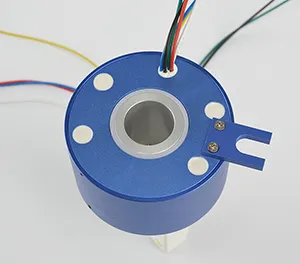

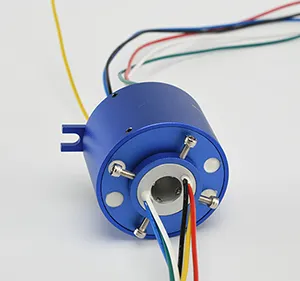

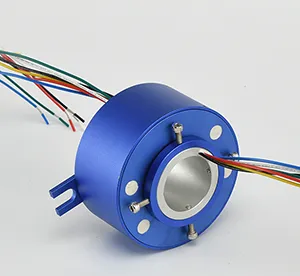

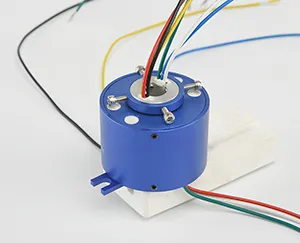

Conductive slip ring product display

Standard conductive slip ring

Other types of slip rings

Provides working principles and technical solutions for various specifications of conductive slip rings.

Pneumatic-electric integrated slip ring

• 360-degree rotation for simultaneous transmission of gas, power signals, and other media;

• Supports 1/2/3/4/5/6/8/12/16/24 gas channels.

• Supports 1~128 power or signal lines.

• Standard interfaces include G1/8″ and G3/8″.

Hat-shaped slip ring

• Cap-type slip rings are a collective term for a series of slip rings with a circular flange attached to the housing. They resemble a cap in appearance, featuring a compact design and small size.

• Typical applications: drones, camera stabilizers, smart homes, security monitoring, photography and videography, robots, testing instruments, turntables, and automated equipment.

RF slip ring

• Supports 1, 2, 3, and 4 high-frequency channels.

• Can mix 1 to 96 power/signal channels.

• Widely used in satellite, radar, mobile antennas, and mobile communication equipment.

Mercury slip ring

• Blade or threaded connector, high speed.

• Capable of transmitting ultra-high currents of 2500A and ultra-low voltage signals.

• Contact resistance < 1 milliohm.

Fiber Optic Slip Ring

• Single-mode and multi-mode options available.

• Fiber optic connectors available in FC, SC, ST, SMA, or LC (PC and APC).

• Fiber optic slip rings support high-capacity data transmission.

• Electromagnetic interference resistant.

air slip rings

•It can stably deliver compressed air, vacuum, or inert gas during continuous 360° rotation of the equipment.

•Supports single or multi-channel gas channel integrated design.

•Adaptable to dynamic working conditions such as rotary tables and robotic arms.

Slip Ring Selection Core Parameter Table

| Core Parameters | Specification/Type Classification | Adaptation Requirements | Typical Applications |

| Speed (RPM) | Low Speed (<100) | Rated speed ≥ 20% of actual speed, copper-graphite contacts | Carousels, low-speed rotating worktables |

| Medium Speed (100-3000) | Rated speed ≥ 30% of actual speed, silver alloy contacts | Industrial robotic arms, ordinary CNC machine tools | |

| High Speed (>3000) | Rated speed ≥ 50% of actual speed, gold-gold contacts | High-speed radar antennas, precision spindle equipment | |

| Current (A) | Microcurrent (<1) | Contact resistance <10mΩ, single-channel rated current ≥1A | Sensor signal transmission, precision instruments |

| Normal Current (1-50) | Total rated current with 20% margin reserved | Ordinary motors, LED lighting systems | |

| High Current (>50) | Special high-current slip ring, good heat dissipation design | Heavy motor drives, large construction machinery | |

| Signal Type | Low-frequency Analog Signal | Ordinary signal slip ring with shielded channels | Audio signals, ordinary sensor signals |

| Digital Signal | Supports corresponding protocols, bit error rate ≤10⁻¹² | RS485, CAN bus control | |

| High-frequency Signal | Special high-frequency slip ring, independent shield layer | Ethernet, HDMI high-definition video | |

| Mixed Signal | Physical isolation between power and signal channels | Multi-functional robotic arms, composite processing equipment | |

| Rated Voltage | 0-440VAC/VDC | Matches equipment working voltage, insulation resistance ≥100MΩ | General industrial equipment, amusement facilities |

| Protection Level | IP54/IP65/IP68 | Choose IP65 and above for outdoor/humid environments | Outdoor rotating equipment, coastal high-salt fog environments |