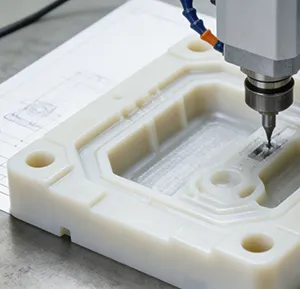

China’s professional CNC machining factory

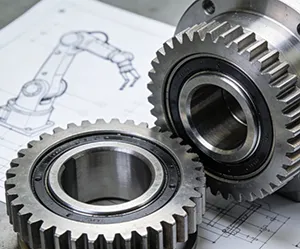

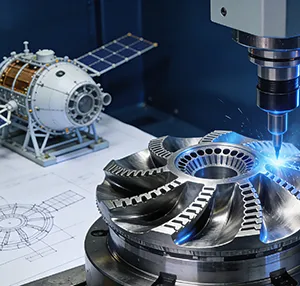

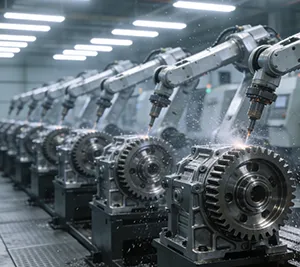

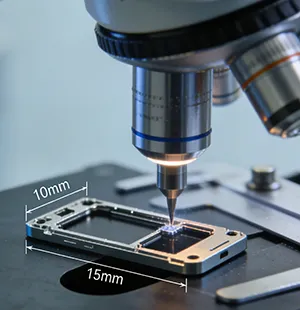

Meticulous craftsmanship in CNC machining: High quality and high efficiency drive intelligent manufacturing upgrades.

| Material | Commonly used | Core Characteristics | Machining Difficulty | Applicable Part Scenarios |

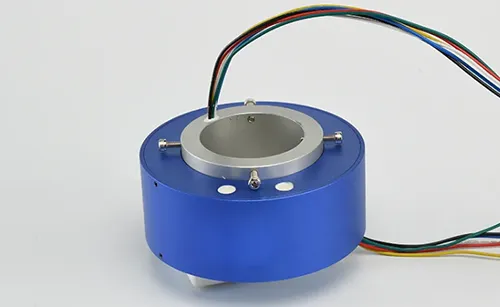

| Aluminum Alloy | 6061, 7075 | Lightweight, easy to cut, cost-effective | Low | Electric slip ring housings, robot lightweight structural parts |

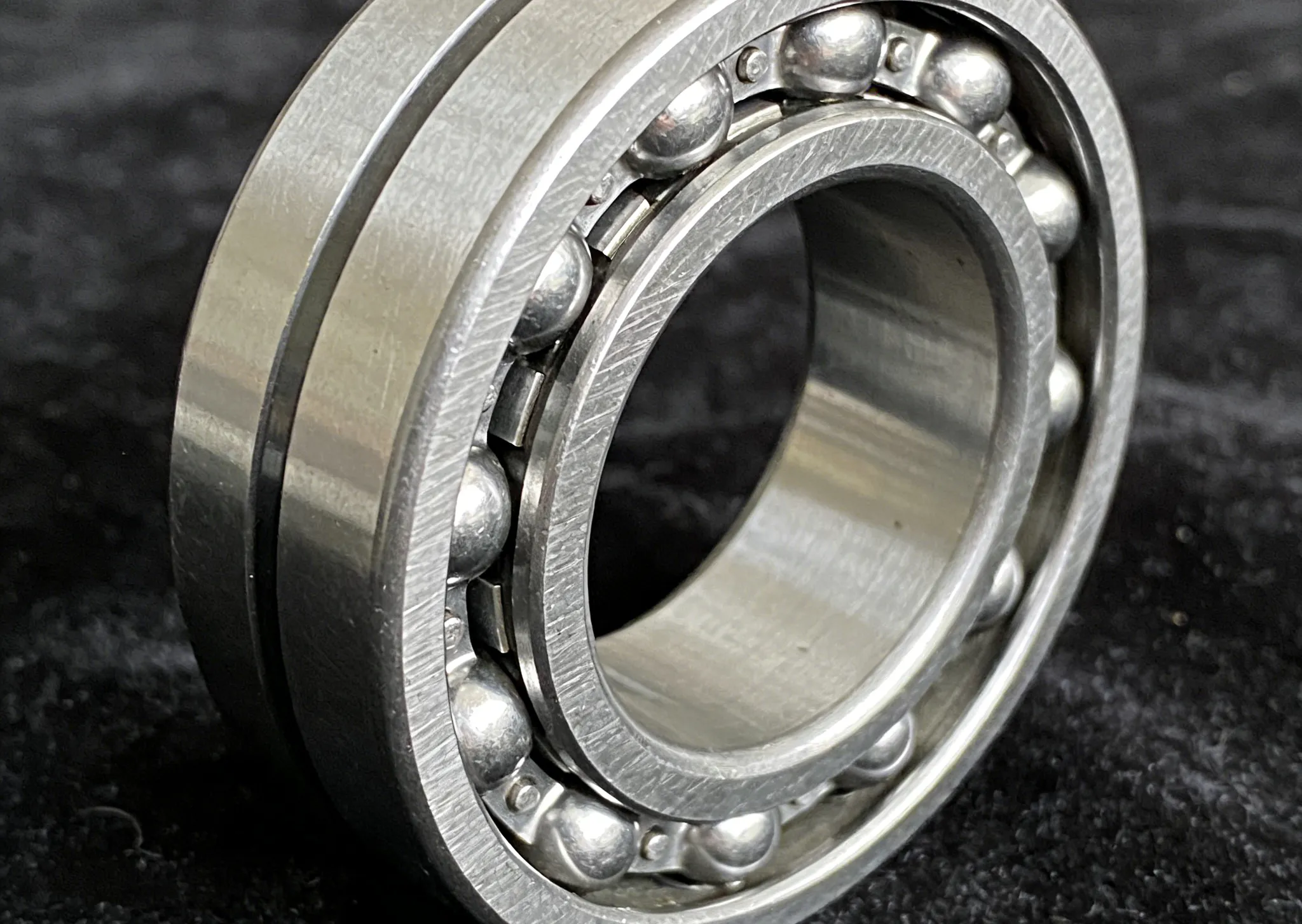

| Stainless Steel | 304, 316 | Corrosion-resistant, high strength, good toughness | Medium | Medical equipment parts, high-precision transmission components |

| Carbon Steel/Alloy Steel | 45# Steel, 40Cr | High hardness, excellent wear resistance | Medium | Robot joint bearing blocks, mechanical transmission shafts |

| Copper and Copper Alloy | Brass, Pure Copper | Good electrical conductivity, excellent thermal conductivity | Low-Medium | Electric slip ring conductive parts, precision connectors |

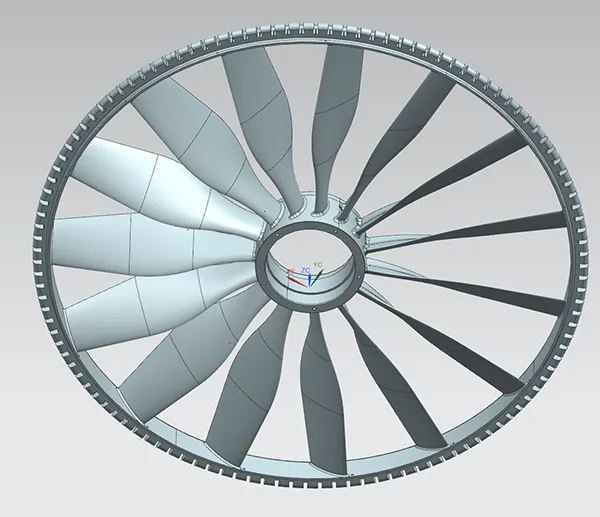

| Titanium Alloy | TC4, TA2 | High strength, resistant to extreme environments | High | Aerospace parts, high-end robot core components |

| Engineering Plastics | POM, PEEK, Nylon | Wear-resistant, insulating, lightweight | Low | Robot joint insulating parts, slip ring insulating brackets |

| Carbon Fiber Composite Material | Carbon Fiber Sheets | High strength, lightweight, good rigidity | Medium-High | High-end robot structural parts |

Parts Machining Services

For further details, feel free to contact us for a complimentary consultation and real-time quote tailored to your needs.

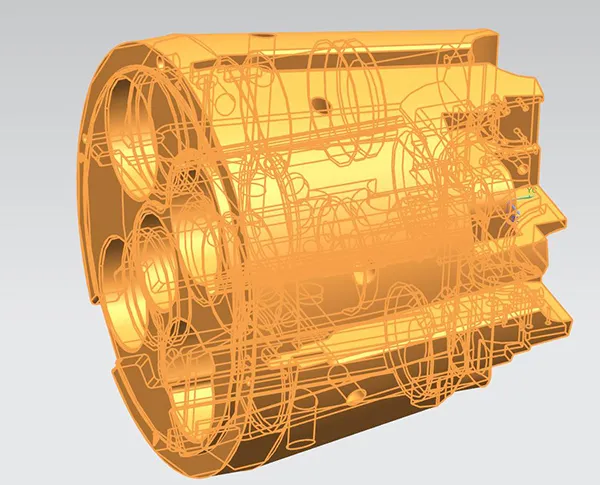

Application Industry

With its advantages of high precision, high consistency, and flexible production, CNC machining covers almost all modern manufacturing fields, and is especially suitable for industries with high requirements for the precision and complexity of parts.Custom CNC machining delivers high-precision, tailored components across core high-value industries—including aerospace, medical devices, automotive, electronics, marine, and robotics—with material and process optimization aligned to each sector’s unique performance, regulatory, and environmental requirements.