China’s professional CNC machining factory

Meticulous craftsmanship in CNC machining: High quality and high efficiency drive intelligent manufacturing upgrades.

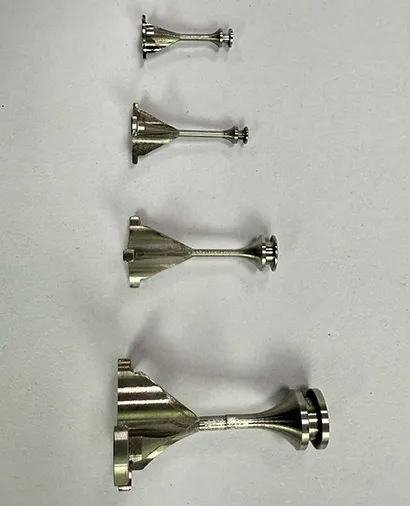

Asemiconductor industry

- Processing Types: Wafer fixtures, vacuum nozzles, probe card assemblies, packaging substrates;

- Core Processes:Ultra-precision five-axis milling, cleanroom machining, machining of ceramic/silicon carbide specialty materials;

- Key Parameters: ±0.001mm accuracy, ISO Class 7 cleanliness, Ra0.01μm surface roughness

- Case Studies: Vacuum nozzle

Electronic device parts

- Machining Types: Miniature shafts, thin-walled housings, camera brackets, etc.

- Core Processes: Precision cutting, wire EDM;

- Key Parameters: ±0.003mm accuracy, φ0.1mm micro-hole, compatible with aluminum alloy/titanium alloy materials.

- Case Studies: Mobile phone camera brackets, industrial control board accessories

Automotive parts

- Processing Types: New energy vehicle motor shafts, gearbox parts, chassis precision components;

- Core Processes: Batch CNC turning, five-axis milling;

- Key Parameters: High and low temperature resistance, fatigue strength, mass production capacity of 500,000 units/month;

- Case Studies: New energy vehicle battery connectors, gearbox gear shafts

Medical device parts

- Processing Types: Surgical instrument accessories, medical sensor housings, implantable parts;

- Core Processes: Precision grinding, burr-free machining;

- Key Parameters: Biocompatible materials (titanium alloy/PEEK), ISO13485 certification;

- Case Studies: Orthopedic implant screws, medical endoscope accessories.

Aerospace parts

- Processing Types: Aerospace structural components, aerospace precision shafts, engine parts;

- Core Processes:High-temperature alloy machining, five-axis simultaneous milling;

- Key Parameters: Machining materials (titanium alloy/high-temperature alloy), aerospace AS9100 certification;

- Case Studies: Aero-engine blades, satellite support components

| Parameter Category | Technical Indicators | Application Scope | Accuracy Assurance |

| Machining Accuracy | Dimensional tolerance ±0.005mm Geometric tolerance ±0.01mm | Precision hardware, medical components, aerospace parts | 100% inspection by Coordinate Measuring Machine (CMM) |

| Machining Materials | Aluminum alloy / Stainless steel / Copper / Titanium alloy / Engineering plastics | Automotive, electronics, medical device industries | Certified material reports from original manufacturers |

| Machining Equipment | 5-axis CNC / High-speed milling / Turn-mill composite machine | Complex curved surfaces, special-shaped precision parts | Regular equipment calibration, accuracy error < 0.002mm |

| Surface Treatment | Anodizing / Electroplating / Passivation / Sandblasting | Improve wear resistance and corrosion resistance | Surface roughness Ra ≤ 0.8μm |

| Production Capacity | Custom single-piece / Batch production (1–10,000 units) | Prototype sampling, mass order production | Standardized production line, yield rate ≥ 99.5% |

| Delivery Cycle | Samples: 3–5 days Batches: 7–15 days | Urgent orders / Regular orders | Intelligent scheduling system, on-time delivery rate 100% |

Precision parts machining services

Our CNC machining services encompass a complete service system covering basic machining to specialized machining, and from single-piece prototyping to mass production, catering to various machining processes, customization needs, and supporting services.

CNC turning

It is mainly used for machining rotating parts such as shafts, discs, and sleeves, and can complete processes such as turning the outer diameter, turning the inner hole, turning the thread, chamfering, and cutting.

CNC milling

CNC milling uses a numerical control system to drive the cutting tool to mill the workpiece, integrating multiple processes into one machining operation, suitable for mass production of parts.

Electrical Discharge Machining

This method utilizes electrode discharge to remove workpiece material, making it suitable for difficult-to-cut metals, and achieving high machining accuracy and good surface quality.

CNC grinding

Using grinding wheels and other abrasive tools to cut workpieces, it achieves high precision (±0.0005–0.001mm) and good surface finish, making it suitable for the final machining of precision parts.

Our CNC machining products

CNC machining of high-precision parts, multi-material compatible, flexible production with fast response, international quality compliant.ch image unveils a unique story from the heart of nature.

Laryngoscope parts

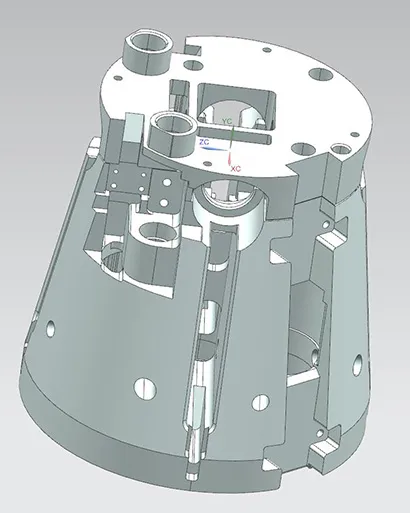

gyroscope

Valve body parts

| Equipment Name | Type | Brand | quantity | Machining accuracy | Processing range |

| conventional milling machine | 3HG | Fuji Sangyo | 3 | 0.02 | X-850 Y-500 Z-1000 |

| CNC lathe | CK7516A | DMG | 3 | 0.002-0.005 | Rotation diameter 350 mm, length 400 mm, with tailstock |

| CNC lathe | CK40 | DMG | 2 | 0.002-0.005 | Rotation diameter 350 mm, length 400 mm, with tailstock |

| CNC machining center | HVM6 | DMG | 2 | 0.002-0.005 | X-600 Y-400 Z-500 |

| CNC machining center | VMC850L | Mazak | 1 | 0.002-0.005 | X-840 Y-550 Z-550 |

| CNC machining center | VMC600L | Mazak | 1 | 0.002-0.005 | X-550 Y-430 Z-550 |

| CNC machining center | HVM6 | DMG | 1 | 0.002-0.005 | X-600 Y-400 Z-500 Four-axis:X-400 Y-250 Z-250 |

| CNC machining center | V6 | DMG | 2 | 0.002-0.005 | X-600 Y-400 Z-500 |

| CNC machining center | MC850L | Kezon | 1 | 0.002-0.005 | X-840 Y-550 Z-500 Four-axis:X-400 Y-250 Z-250 |

| CNC machining center | VCN-430A | Mazak | 6 | 0.002-0.005 | X-550 Y-430 Z-550 |

| CNC machining center | 850L | Baojia CNC | 1 | 0.002-0.005 | X-840 Y-550 Z-550 |

| CNC machining center | VCN-430AL | Mazak | 4 | 0.002-0.005 | X-550 Y-430 Z-550 Four-axis:X-400 Y-250 Z-250 |

| CNC machining center | CMX600VC | DMG | 2 | 0.002-0.005 | Five-axis:X-500 Y-450 Z-380 |

| CNC machining center | DMU500 | DMG | 4 | 0.002-0.005 | X-600 Y-400 Z-500 |

| CNC lathe | CK-45TW | Kezon | 3 | 0.02 | Customized according to product precision |

| Milling and turning | CKF-52YW | Kezon | 2 | 0.002-0.005 | Customized according to product precision |

| CNC Swiss-type machine | BO205A | Tsugami | 2 | 0.002-0.005 | Customized according to product precision |

| centerless grinding machine | RC-18C | Taiwan Rongguang | 2 | 0.002-0.005 | Customized according to product precision |

| centerless grinding machine | JHC-18S | Taiwan Jianhe | 2 | 0.002-0.005 | Customized according to product precision |

| punch grinder | JAG01 | Taiwan Qiaojia | 2 | 0.002-0.005 | Customized according to product precision |

| Precision surface grinder | 618S | Taiwan Wangpan | 1 | 0.002-0.005 | Customized according to product precision |