Gyroscopes

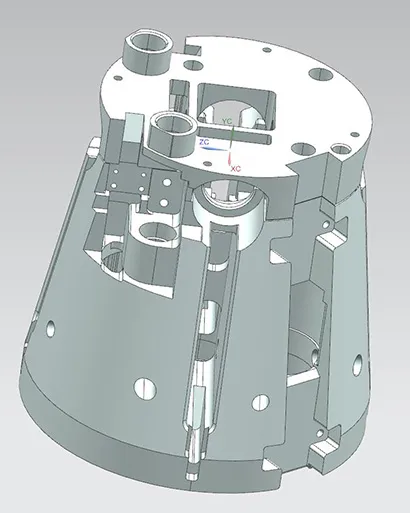

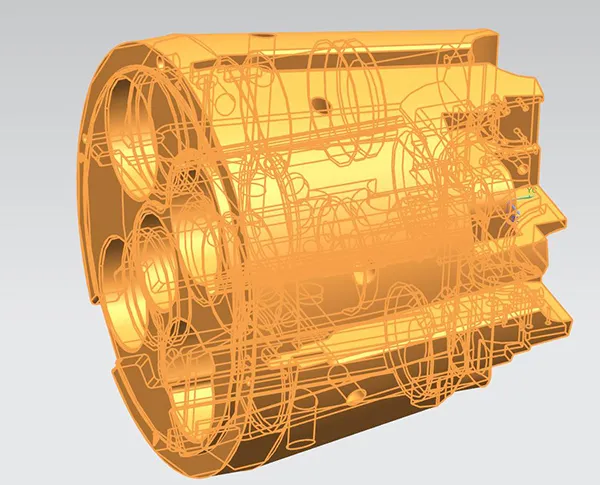

Gyroscopes stand as the core precision components powering navigation systems, aerospace guidance, and industrial robotics—where even micron-level deviations can compromise performance. Our CNC machining facility specializes in crafting custom gyroscope components with uncompromising accuracy, leveraging 5-axis machining technology to tackle complex geometries like rotor hubs, gimbal frames, and sensor housings. We work with high-strength alloys, aerospace-grade aluminum, and advanced ceramics, adhering to tight tolerances of ±0.001mm to ensure rotational stability and durability under extreme conditions. Every gyroscope part undergoes rigorous in-process inspection, from raw material testing to final dimensional verification, guaranteeing compliance with ISO 9001 and AS9100 standards. For industries demanding reliable, high-performance gyroscope solutions, our precision machining capabilities deliver parts that meet the most stringent operational requirements.

| Parameter Category | Specific Index | Technical Description |

| Machining Precision | Dimensional Tolerance ±0.002 mm | Meets the micron-level assembly requirements of core gyroscope components |

| Geometric Tolerance ≤0.003 mm | Ensures the coaxiality and parallelism of components such as rotors and brackets | |

| Surface Quality | Surface Roughness Ra 0.2 μm | Reduces friction resistance during high-speed rotation and improves stability |

| Material Performance | Adopting Aerospace-grade Aluminum Alloy/Titanium Alloy | Lightweight design with high rigidity and corrosion resistance |

| Rotational Speed Adaptability | Supports stable operation at up to 10000 r/min | Suitable for high-speed working conditions of high-precision navigation gyroscopes |

| Temperature Adaptability | Operating Temperature Range -40℃ ~ +85℃ | Meets the usage requirements of complex environments such as aerospace and vehicle-mounted applications |

| Quality Inspection Standard | 100% inspection of first article + 30% sampling inspection of batch products | Controls defect rate below 0.5% and ensures qualification rate ≥ 95% |