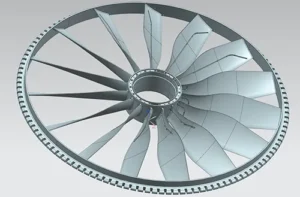

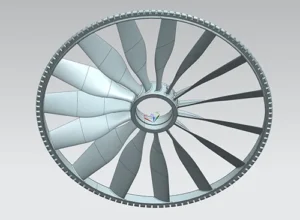

The impeller is a core rotating component of power equipment such as aero-engines, turbines, and water pumps. Its machining precision directly determines the hydrodynamic efficiency, operational stability, and service life of the equipment. Professional impeller CNC machining manufacturer, providing 5-axis linkage forming, high precision (error ≤0.003mm), high efficiency & low consumption processing services, suitable for aerospace/energy/water conservancy industries, customized solutions.The following are the core parameters and processing advantages of targeted CNC precision cutting:

Core Machining Parameters

| Parameter Category | Core Indicators | Technical Value |

| Machining Precision | Blade profile tolerance ±0.005 mm Concentricity between blade tip and hub ≤0.003 mm Blade thickness deviation ≤0.002 mm | Ensures air/liquid flow stability, reduces operating noise and energy consumption |

| Surface Quality | Blade surface roughness Ra 0.1 μm Deburring treatment, edge chamfer R0.05 mm | Reduces fluid resistance, improves impeller aerodynamic/hydraulic efficiency |

| Material Adaptation | Aluminum alloy (2024/6061), Titanium alloy (TC4) tainless steel (316L), Superalloy (Inconel 718) | Meets different working condition requirements; superalloy adapts to high-temperature aerospace environments |

| Dynamic Balance Performance | Dynamic balance grade G2.5 (rotational speed ≤10000 r/min Dynamic balance grade G1.0 (rotational speed >10000 r/min) | Avoids vibration during high-speed rotation, extends equipment service life |

Core Processing Advantages

- High-Precision Forming: Adopts 5-axis linkage CNC machining technology to realize one-time clamping forming of complex blade profiles, effectively reducing clamping errors and ensuring consistent precision between multiple blades (error ≤0.003 mm).

- High Efficiency & Low Consumption: Integrates CNC polishing and ultrasonic cleaning processes to replace traditional manual grinding, improving processing efficiency by more than 40%, while avoiding blade surface damage and ensuring aerodynamic performance.

- Strict Quality Inspection Guarantee: Key dimensions are fully inspected by coordinate measuring machines, and dynamic balance performance is 100% tested by special testing machines. The defect rate is strictly controlled below 0.2%, adapting to high-end equipment assembly requirements.

- Full Working Condition Adaptation: Can customize and adjust materials and processing parameters according to the needs of different industries (aerospace, energy, water conservancy), adapting to complex working conditions from normal temperature and pressure to high temperature and pressure.