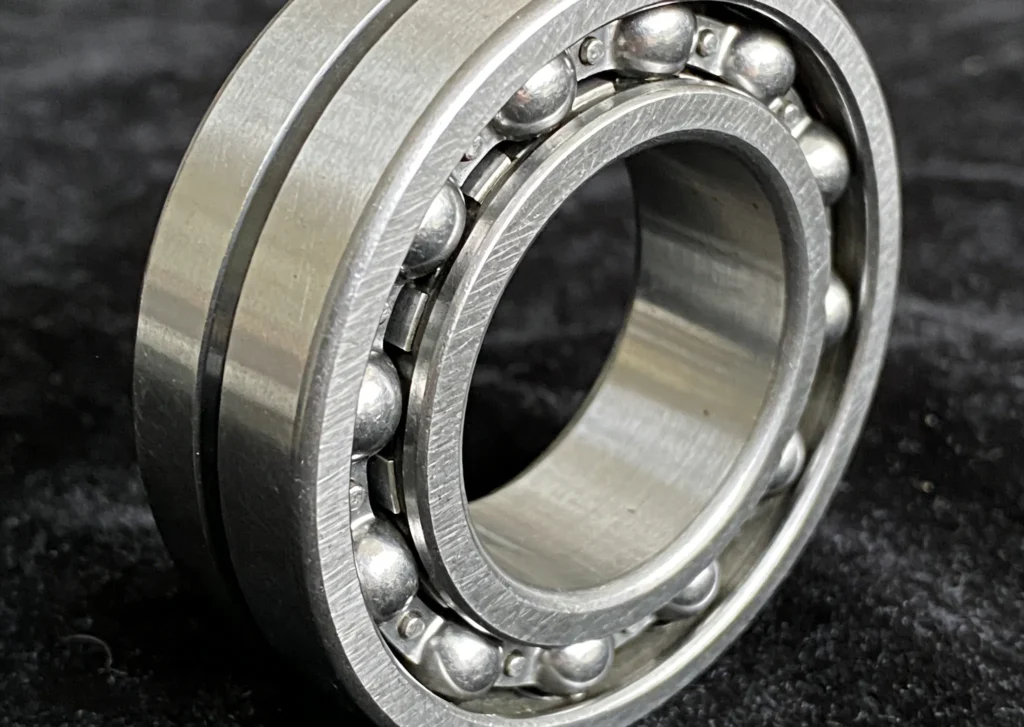

A rolling bearing is generally composed of four parts: outer ring, inner ring, rolling elements and cage. According to the shape of rolling elements, rolling bearings are divided into two major categories: ball bearings and roller bearings. These are the basic components and classifications of rolling bearings, which lay the foundation for their processing technology.

Although there are many types of rolling bearings, with differences in structural types, tolerance grades, material selection and processing methods, their basic manufacturing processes are similar. This similarity ensures the standardization of rolling bearing production and improves production efficiency.

Below, we will briefly introduce the processing technology process of bearing components, which is crucial for understanding the production of rolling bearings.

1. Processing Process of Bearing Rings

The processing of rolling bearing inner rings and outer rings varies according to the type of raw materials or blanks. This is one of the key links affecting the precision of bearing rings.

The entire processing process of bearing rings is as follows:

Bar or pipe (some bars need to be forged, annealed and normalized) → Turning → Heat treatment → Grinding → Lapping or polishing → Final inspection of parts → Rust prevention → Warehousing → (Waiting for matching assembly)

2. Processing Process of Steel Balls

Similarly, the processing of steel balls (an important type of rolling bearing rolling elements) also varies according to the state of raw materials. The precision of steel ball processing directly affects the service life of rolling bearings.

The entire processing process of steel balls is as follows:

Cold stamping of bar or wire (some bars need to be punched with annular belt and annealed after cold stamping) → Filing, rough grinding, soft grinding or光球 → Heat treatment → Hard grinding → Precision grinding → Lapping or grinding → Final inspection and grouping → Rust prevention and packaging → Warehousing (Waiting for matching assembly)

3. Processing Process of Rollers

Rollers are another important type of rolling elements in rolling bearings. The processing of rollers also varies according to the type of raw materials, and its processing precision is related to the stability of rolling bearings during operation.

The entire processing process of rollers is as follows:

Turning of bar or cold heading of wire, then stringing annular belt and soft grinding → Heat treatment → Stringing soft spots → Rough grinding of outer diameter → Rough grinding of end face → Final grinding of end face → Fine grinding of outer diameter → Final grinding of outer diameter → Final inspection and grouping → Rust prevention and packaging → Warehousing (Waiting for matching assembly)

4. Processing Process of Cages

The processing process of rolling bearing cages can be divided into the following two categories according to the design structure and raw materials, which play a key role in fixing rolling elements.

(1) Sheet Metal Cage Processing Process

Sheet metal → Shearing → Blanking → Stamping forming → Shaping and finishing → Pickling, shot blasting or stringing → Final inspection → Rust prevention and packaging → Warehousing (Waiting for matching assembly)

(2) Solid Cage Processing Process

The processing of solid cages varies according to raw materials or blanks. Before turning, there are four types of blanks: bar, pipe, forging and casting. The entire processing process is as follows:

Bar, pipe, forging, casting → Turning inner diameter, outer diameter, end face and chamfer → Drilling (or broaching, boring) → Pickling → Final inspection → Rust prevention and packaging → Warehousing (Waiting for matching assembly)

The above is a brief introduction to the rolling bearing processing technology. At present, bearing processing is developing in the direction of high metal material utilization rate, high production efficiency and high forming precision, which promotes the progress of the entire rolling bearing industry.