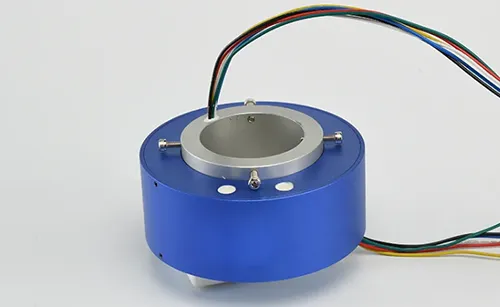

Slip rings are precision components and therefore require careful handling. As core transmission parts that enable continuous rotation while conducting electricity, signals, or fluids, slip rings are widely applied in high-precision fields such as industrial automation equipment, medical devices, aerospace instruments, and marine navigation systems. Their internal structure consists of intricate components including conductive rings, brushes, insulators, and bearings, each processed with strict dimensional accuracy and surface finish requirements to ensure stable and low-noise transmission performance. Even with different types of slip rings—whether miniature capsule slip rings for small electronic devices, through-bore slip rings for large rotating machinery, or high-frequency slip rings for signal transmission—improper use can lead to underperformance or even damage.

The following measures:

1.Keep surrounding environment clean

Even tiny dust particles invisible to the naked eye can exacerbate wear, vibration, and noise. These minuscule particles, often composed of metal shavings, dust mites, or industrial residues, can easily infiltrate the minute gaps between the slip ring’s conductive rings and brushes.

Once trapped, they act as abrasive particles during the high-speed rotational contact, significantly accelerating the wear of both components, disrupting the stable contact between the brush and ring, and thereby increasing vibration and generating abnormal noise that impairs the slip ring’s transmission stability.

2.Install slip rings carefully.

When installing an electrical slip ring, strictly follow standard procedures.

Never press the slip ring body excessively: its internal conductive rings, brushes and bearings are pressure-sensitive, and over-pressing may cause deformation, surface scratches or bearing clearance offset, compromising power and signal transmission stability.

Never strike it directly with hard tools like hammers: violent impacts will damage structural precision, leading to abnormal contact resistance, rotation jams or seal failure that allows dust and moisture intrusion.

Never transfer pressure via its rolling elements: these core components for support and rotation guidance may deform or wear prematurely under external force, shortening the slip ring’s service life and causing equipment vibration and noise issues.

3.Use appropriate and precise installation tools.

During the installation, commissioning and daily maintenance of conductive slip rings, special tools of the appropriate model should be used as much as possible.

These tools are precisely designed to perfectly match the structural characteristics of the slip rings, which can effectively avoid scratches, extrusion and other damages to the precision components such as the conductive ring surface and brushes, and ensure the safety and standardization of operations.

At the same time, it is imperative to avoid using short-fiber materials such as cloth and paper towels to contact the key parts of the slip ring. Such materials are prone to shedding fine fibers during contact.

These fibers will seep into the internal gaps of the slip ring and adhere to the conductive contact surface, thereby affecting the stable transmission of current or signals, accelerating the wear of components, and even causing failures in severe cases.

4.Prevent rust.

Before any direct contact with an electrical slip ring for operation, thoroughly clean your hands to remove sweat, oil stains and dust impurities.

The salt and moisture in sweat are corrosive; once they adhere to the surface of precision components such as the slip ring’s conductive rings and brushes, they will easily cause metal oxidation and rust, damage the smoothness of the contact surface, and then lead to increased contact resistance and unstable signal transmission.

After cleaning, evenly apply high-quality mineral oil to the contact area to form a protective film that isolates moisture and contaminants.

Pay special attention to rust prevention in rainy seasons and hot, humid summers, when high air humidity sharply increases the risk of metal corrosion. Strengthen cleaning, protection and regular inspections to avoid rust damage from the source.

Due to significant differences in working environments and conditions,under certain special circumstances or conditions,especially under light loads,the service life of them can be longer than traditionally calculated.

These special operating conditions refer to the effective separation of rolling surfaces(tracks and rolling elements)by a lubricating oil film,thus limiting surface damage that contaminants may cause.In fact,under ideal conditions,the durability and long lifespan of them are entirely achievable.I have long studied slip ring issues in factory equipment maintenance.Generally,it’s best to add mercury after removing the protective cover from a new slip ring.It can be used without adding mercury,but not for extended periods,especially given the current market flooded with counterfeit and substandard products.Even if you spend a significant amount of money purchasing them,you may not be able to buy genuine products.

Therefore,once a quality problem is encountered,lubricating oil must be added.Please remember that the quality of slip rings,especially mercury slip rings,is crucial to the safety of motors and workers!We have paid a heavy price for this.Lithium molybdenum disulfide grease is best used for them because of its heat resistance and wear resistance.

The lifespan of a rolling slip ring is defined in revolutions(or hours of operation at a specific speed):within this lifespan,any ring or rolling element of the slip ring should show initial fatigue damage(stripping or breakage).However,whether in laboratory testing or in actual use,it is obvious that slip rings with the same appearance and the same working conditions may have vastly different actual service lives.